Virtual CNC

Overview

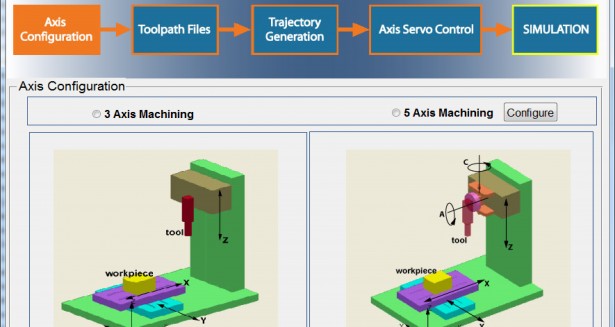

Virtual CNC is a powerful module which provides a comprehensive simulation environment for CNC design engineers and users simulate a wide range of performance-related properties of Cartesian-Configuration CNC machine tools before the actual machining process. This way expensive and time-consuming trial and error cuts can be reduced.

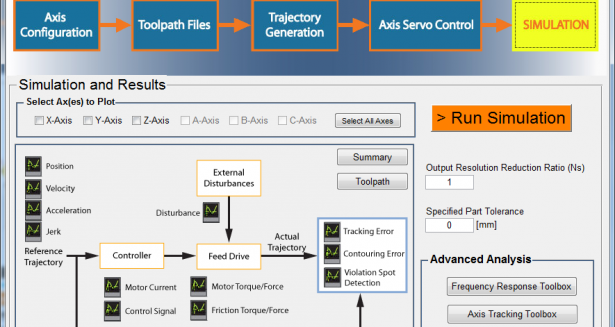

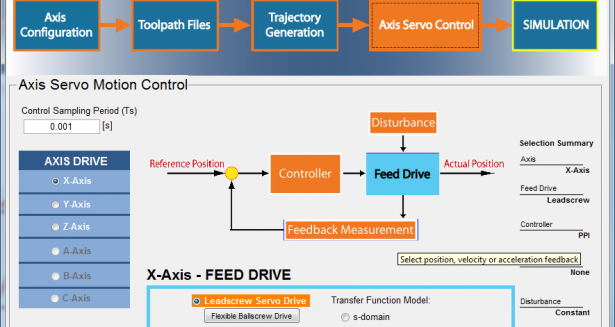

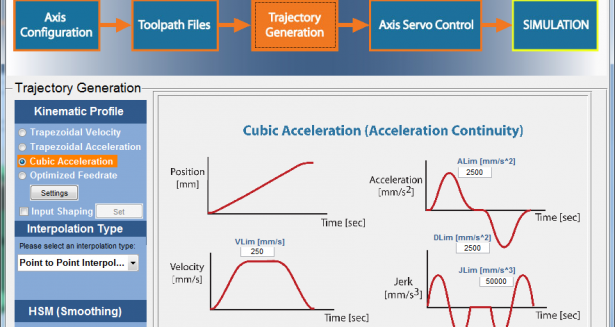

It accepts standard APT-CL files, processed them exactly like a real CNC. The user can define trajectory generation style, amplifier settings, position (encoder), velocity (tacho generator) and acceleration feedback sensors and their resolutions, and axis control laws. The Virtual CNC system predicts the actual positions delivered by the CNC, and plots the reference and predicted actual paths, the tolerance violation points along the tool path, cycle time by accurately calculating the feed fluctuations caused by acceleration/deceleration and control law, motor current, and position-displacement and acceleration of each drive. Virtual CNC allows testing of different control laws, friction fields, motors, sensors, ball screws and trajectory generation algorithms.

It also provides time and frequency domain response of individual drives, as well as testing of the CNC on ISO standard test workpieces such as diamond and circle. Virtual CNC can be used by manufacturing shop engineers as well as by the CNC designers and professors who teach position control of motion devices. For more details please contact us.

Virtual CNC offers the following features:

- Step-by-step CNC Model Generation

- Detailed CNC Performance Simulation

- CNC Advanced Controller Design/Analysis Tools