DELPro: DELMIA™ Dynamic Tool Path Optimization

Available early 2021

Overview

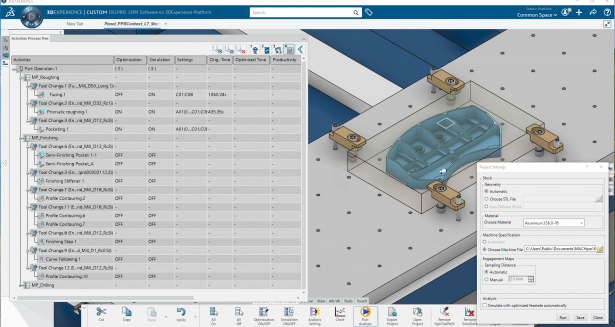

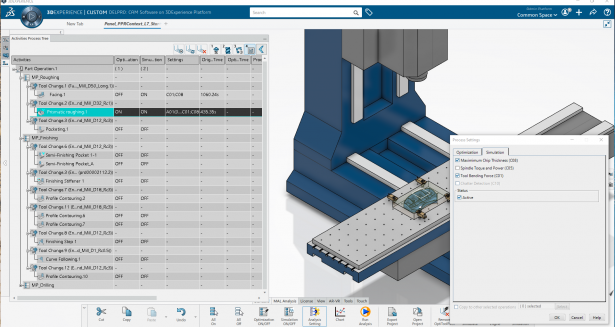

Manufacturing Automation Laboratories. Inc has partnered up with Dassault Systems to offer a physics-based machining process simulation and feed-rate optimization tool called “DELPro – DELMIA Dynamic Tool Path Optimization”.

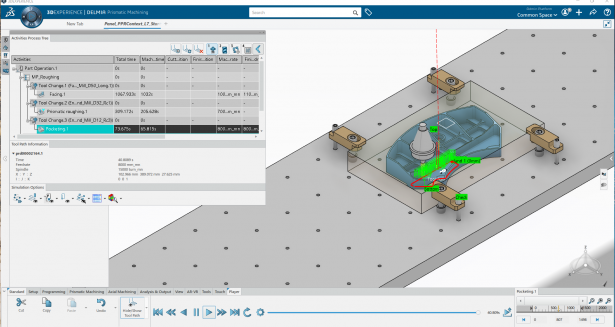

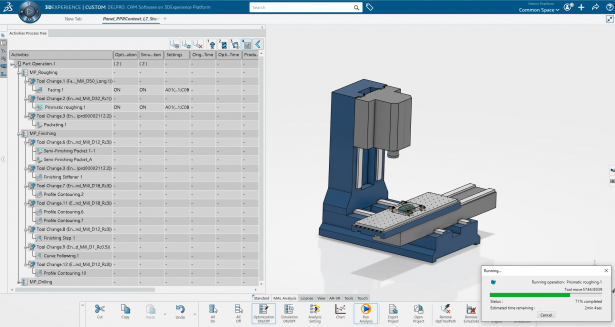

DELPro helps the NC programmer to predict how the tool will perform on the machine based on physics simulation and to optimize the tool path prior to G-Code generation so as to reduce the machining time while increasing tool life and process security before resorting to costly physical trials. With DELPro, machining is now optimized without ever having to operate machinery, cut material, scrap parts, break tools, crash spindle bearings, create machine downtimes and more.

DELPro provides unprecedented control and insight into the machining operation. Unlike other NC program optimization products that adjust feed rate purely on the volume of material removed, DELPro considers the geometry of the chip being removed, workpiece material properties, tool geometry, and tool motion. This deep understanding of metal cutting physics is applied to the machining process to produce precise high quality machined surfaces at higher material removal rates.

DELPRO Features

DELPro is a fully integrated physics-based plug-in (not a file exchanger) that:

- works smoothly within the 3DEXPERIENCE environment

- is easy to set up and get started with feed rate optimization

- requires a small number of settings, which can be easily filled in by NC Programmers

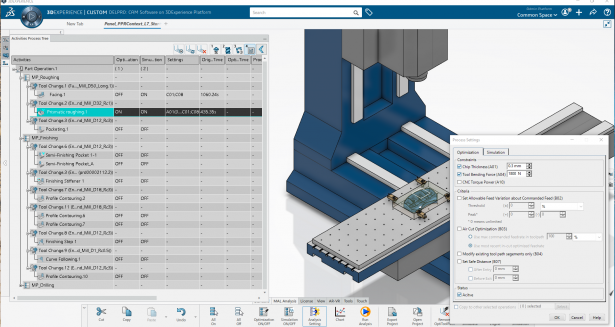

- provides physics-based tool path verification to avoid tool/machine overload or part violations, which cannot be detected otherwise

- optimizes existing tool path feed rates based on metal cutting physics to obtain better, faster, safer and smarter feed rates for a variety of applications including 2.5, 3, and 5 axis

DELPro toolboxes

NC Program Diagnosis

This toolbox provides a quick and accurate estimation of machining performance by emulating actual metal cutting process and detecting process mishaps such as:

- spindle overload – torque/power violations

- excessive cutting forces… hence tool deflection/breakage, part distortion, fixture instability

- unbalanced chip load… hence premature tool wear, tool chipping

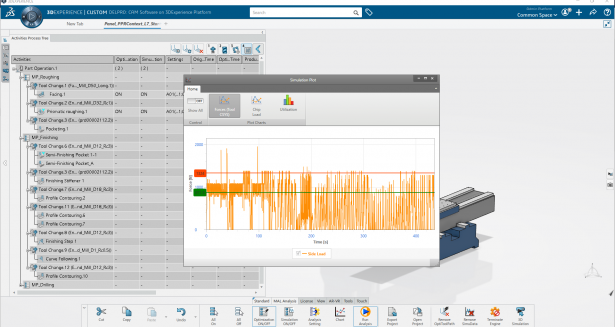

NC Program Optimization

DELPro optimizes feed rates of an existing NC program within user-defined limits such as maximum chip load, spindle torque/power, and cutting forces. The advanced optimization kernel of DELPro dramatically reduces cycle time without jeopardizing process security. Consequently, optimized NC programs improve tool life, reduce equipment wear and tear and eliminate productivity obstacles.